METHOD FOR PROCESSING TEETH OF GEAR COUPLING

2024-03-26 15:00The processing method of gear coupling teeth is determined based on its structure, shape and machine tools equipped in the workshop. Normally, the external teeth of the rigid gear coupling are milled or hobbing. The internal teeth of the crowned teeth coupling are processed by gear shaping;The concentricity of the center line of the indexing circle of the internal and external teeth of the gear spindle couplings and the center line of the shaft and the contact condition of the teeth are important. In order to improve the gear degree of the gear type coupling, the gears of the gear joint couplings need to be shaving.

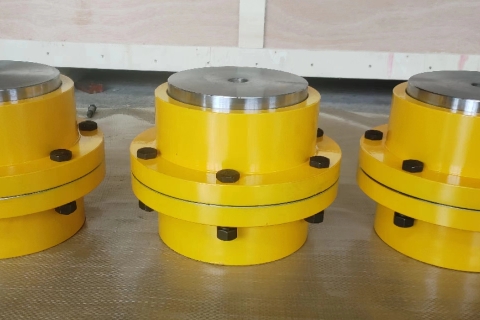

The surface of the teeth-shaft coupling gear generally undergoes surface hardening heat treatment such as quenching, which can improve the hardness of the working surface and maintain good impact toughness inside the Drum - shaped teeth-shaft coupling gear.After quenching, the gear of the gear spindle couplings will inevitably deform and the gear degree will decrease. The surface hardness of the teeth of the rigid gear coupling is very high.After the teeth of the gear type coupling are machined, the connecting bolts on the internal gear sleeve flange can be drilled.