Why choose composite couplings?

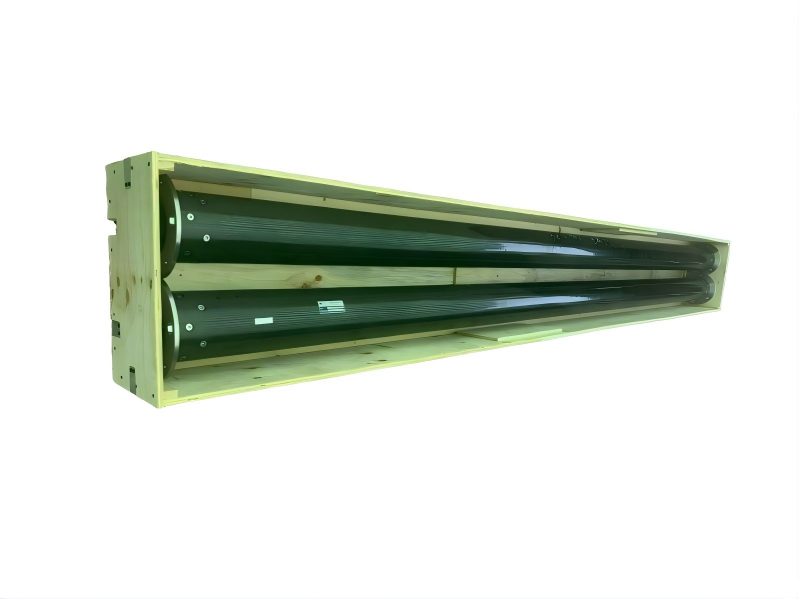

2026-01-23 16:52Composite couplings are advanced couplings specially designed for high-speed and corrosive environments such as cooling tower fans. Manufactured from high-performance carbon fiber composite materials, they subvert the design concept of traditional metal couplings and bring revolutionary performance improvements to core equipment.

Core Advantages and Features

1. Ultra-lightweight: Manufactured from carbon composite materials, it weighs only 20% of that of traditional steel counterparts. This significantly reduces rotational inertia, lowers the start-stop load of fans, and achieves energy saving and consumption reduction. The length of the composite coupling can be increased by 80% compared with steel couplings, providing greater flexibility for equipment layout. Additionally, it eliminates the need for installing support bearings, simplifies the structure, and reduces installation and maintenance costs.

2. Excellent Dynamic Balancing and High-Speed Capability:

The coupling is precisely dynamically balanced in strict accordance with ISO 1940-1, balance quality grade G6.3, ensuring excellent rotational balance performance.

Its superior balancing performance, combined with a high specific stiffness, makes it particularly suitable for high-speed operating conditions, delivering smooth operation with low vibration. This effectively protects motor and fan bearings.

In addition, regular adhesive bond strength testing is conducted as part of quality control to ensure that the bonded interfaces can reliably transmit the maximum design torque, thereby guaranteeing the safety and continuity of power transmission.

3. Excellent Environmental Resistance and Long Service Life

a. Moisture-resistant coating:

The composite material surface is treated with a special protective coating to effectively prevent moisture ingress and maintain stable material properties.

b. Resistance to corrosion fatigue:

The composite material itself offers excellent corrosion resistance. Combined with the protective coating, it can operate reliably for long periods even in exposed environments with high humidity or chemical corrosion.

c. High fatigue life:

Thanks to the outstanding fatigue resistance of the composite material, its service life under cyclic loading is significantly longer than that of metallic materials, ensuring extremely high reliability.

Comparison between composite couplings and traditional couplings

| Feature | Composite Coupling | Traditional Steel Coupling |

| Weight | Ultra-light (approx. 20% of steel) | Heavy |

| Length potential | Can be significantly extended (+80%) | Limited by shaft deflection |

| Support requirement | Usually no intermediate support required | Usually no intermediate support required |

| Dynamic balancing | Excellent, easy to achieve high balance grades | Good, but significantly affected by weight |

| Corrosion resistance | Excellent, no rust | Requires coating or stainless steel, otherwise prone to corrosion |

| Fatigue resistance | Excellent | Moderate, with a defined fatigue limit |

| Maintenance requirement | Low (lubrication-free, fewer components) | Low (lubrication-free, fewer components) |

Kudosworld composite couplings effectively address multiple challenges of cooling tower fans, including lightweight design, long shaft span capability, maintenance-free operation, corrosion resistance, and high reliability.

They are not merely transmission components, but a key upgrade solution that enhances the overall efficiency, reliability, and service life of cooling tower fan systems.

For more information and technical consultation regarding our composite couplings, please contact Kudosworld.