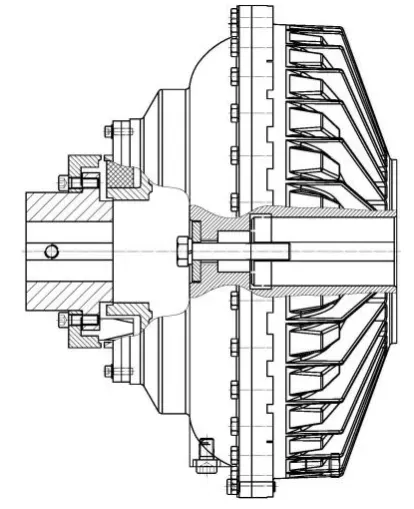

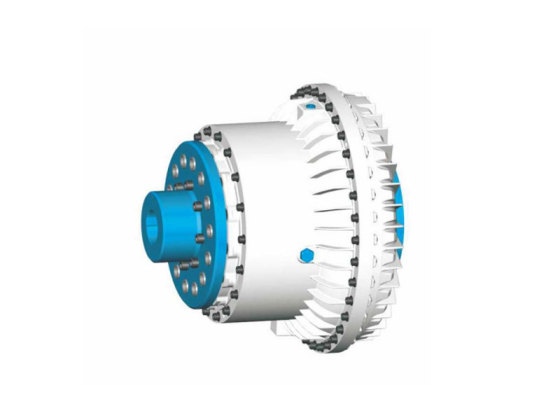

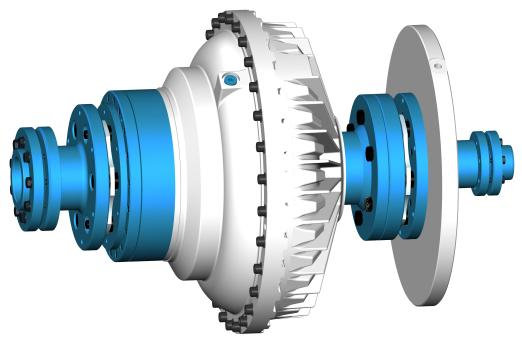

Basic Hydrodynamic Coupling Without Delay Chamber

1.The Hydrodynamic coupling can protect the power drive system from overload.

2.Kudosworld Fluid drive coupling has a special patented design chamber to achieve a more perfect soft start.

- KUDOSWORLD

- GERMANY/CHINA

- 6-10 WORKING WEEKS

- 2,000SETS/YEAR

- Information

- Video

- Download

Hydrodynamic coupling, also known as fluid coupling, is a hydraulic transmission device used to connect the power source (usually the engine or motor) with the working machine and transfer the torque by the change of the liquid momentum.

Hydrodynamic couplings belong to the group of hydrodynamic power transmission devices.

The allowable ambient temperature range of the standard design of the hydrodynamic coupling is - 25 ℃ to + 40 ℃ (other values are required).

This limited torque hydraulic coupling has basic structure without a delay chamber.

This type of fluid drive Coupling's soft start time is around 20 seconds.

Typical Applications

1. Large load acceleration machinery, such as rolling mill, centrifuge, mixer, blower, carpenter, screen machine, ball mill, cable machine and machine tool.

2. Avoid high impact torque machinery during startup, such as mixer, belt conveyor, crusher, centrifuge and pump.

3. Soft start protection and regulation on large mobile equipment.

4. Safe overload protection machinery such as dredger, crusher and bucket wheel machine.

Types of KUDOSWORLD Hydrodynamic coupling

Type HR

·Hydrodynamic coupling without delay chamber

Type HR-C

·Hydrodynamic coupling with delay chamber

Type HR-CC

·Hydrodynamic coupling with enlarged delay chamber

Type HR-D

· Hydrodynamic coupling with two hydrodynamic units

Type B

· Hydrodynamic coupling with brake drum

Ex):HR-B, HR-CB, HR-CCB, HR-DB

Type S

· Hydrodynamic coupling with brake disc

Ex):HR-S, HR-CS, HR-CCS, HR-DS

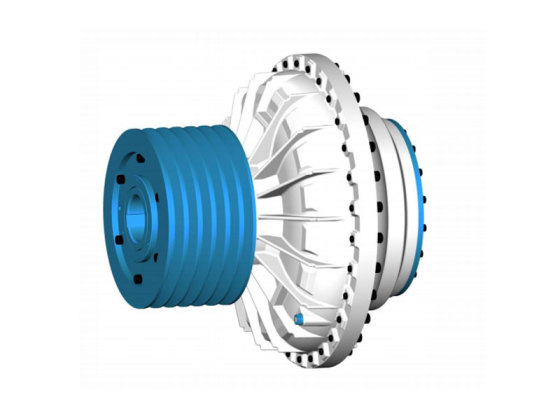

Type P

· Hydrodynamic coupling with pulley

Ex):HR-P, HR-CP, HR-CCP

Type MRR

·Hydrodynamic coupling can be removed without moving both ends

·With flexible connecting coupling

Type MRW

·Hydrodynamic coupling can be removed without moving both ends

·Without flexible connecting coupling

Type MB

·The motor end bears the weight of the Hydrodynamic coupling

·With flexible connecting coupling

Optional Accessory

Water medium

Water medium is more easy to purchase and meets high environmental requirements. The Hydrodynamic couplings can operate normally with water and glycol mixture as medium. Hydrodynamic couplings with water medium need to add encapsulated devices such as oil seals or bearing sealing end caps to seal the bearings. Rolling bearings do not need to be filled with oil, but only need grease to ensure service life. When the water medium is used, the total length of the product will increase.

Balancing Test

Hydrodynamic couplings will be dynamically balanced. Standard balancing quality is Q6,3 at 1500rpm according to VDI 2060 in two planes.

***If you need to choose other balanced quality standards, please contact us.

Insert shaft sleeve

The use of the inserted shaft sleeve can meet the requirements of different shaft diameters and shaft lengths. The inserted shaft sleeve can be processed and shipped according to the user's requirements.

Fusible plug

When the liquid temperature exceeds the melting point of the fusible plug, the fusible plug is ejected. In this way, the Hydrodynamic coupling is protected from overheating. Fusible plugs have a variety of temperature options.

Mechanical thermal switch device

The mechanical thermal switch is set with a lower temperature than the fusible plug to provide secondary protection for Hydrodynamic coupling. When the temperature of the temperature control plug of the mechanical switch is reached, a mechanical signal will be sent from the top of the temperature control plug. After the signal is obtained, the drive system will be cut off.

Electronic thermal switch device

Similar to the mechanical switch, it is a secondary protection for Hydrodynamic coupling from overheating. When the Limit temperature is reached, the sensor will send an electronic signal to the analysis unit and converted into another signal to cut off the drive system.

Protective cover

It is necessary to install a protective cover in order to avoid unintentional contact with the rotating elements of Hydrodynamic couplings. The manufacturing of the protective cover fully considers the cooling of the coupling through air circulation. We can provide standard protective cover or special designs according to customer requirements.

Global Group Company

Kudosworld is an industrial technology group with businesses all over the world. We provide a series of solutions, including advanced technology, manufacturing, products and precision services. Provide products and services for key markets such as new energy, oil and gas, mines, ports, steel, etc. We take Kudosworld (China) as the core of operation and management, rely on the technology of Kudosworld in Germany, and cooperate with global production bases for processing and manufacturing. Over the past decades, we have made contributions to the development and implementation of hundreds of projects where product quality, technological progressiveness and reliability are the prerequisites for success. From finding the best customer solution to complex project delivery, customer trust proves our experience, reliability and professionalism.