- Home

- >

- Products

- >

- Wire Drum Coupling

- >

Wire Drum Coupling

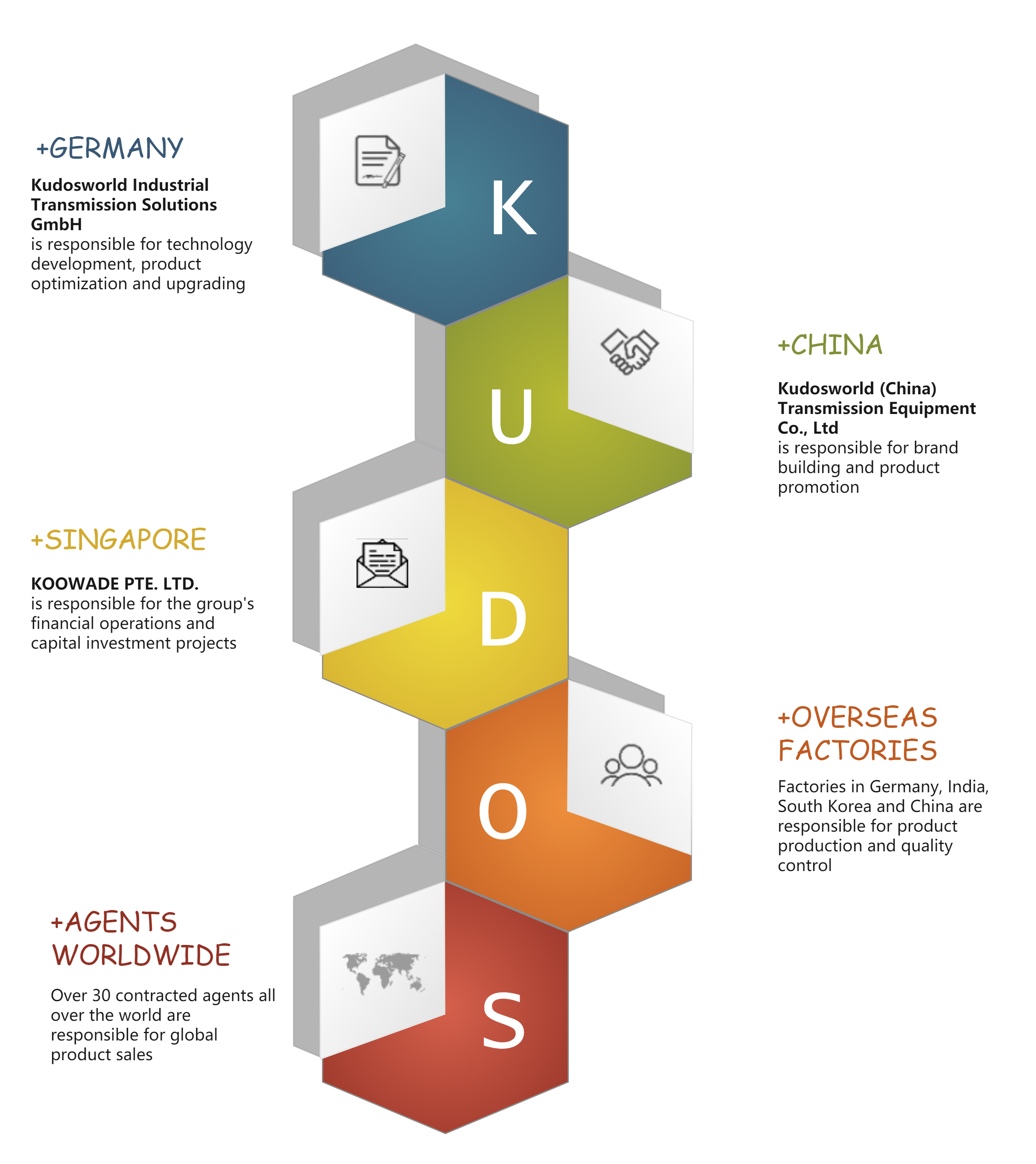

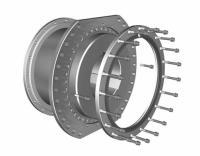

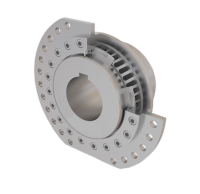

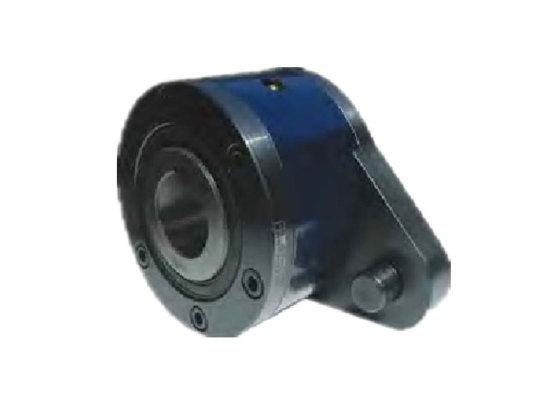

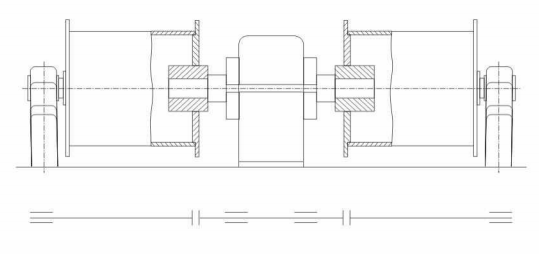

1.KUDOSWORLD Wire Drum Coupling is designed for installation in drum drive of crane and conveying system.

2.The drum coupling can be used in very difficult and rough operating conditions of iron and steel work and continuous heavy load operation in shore cranes

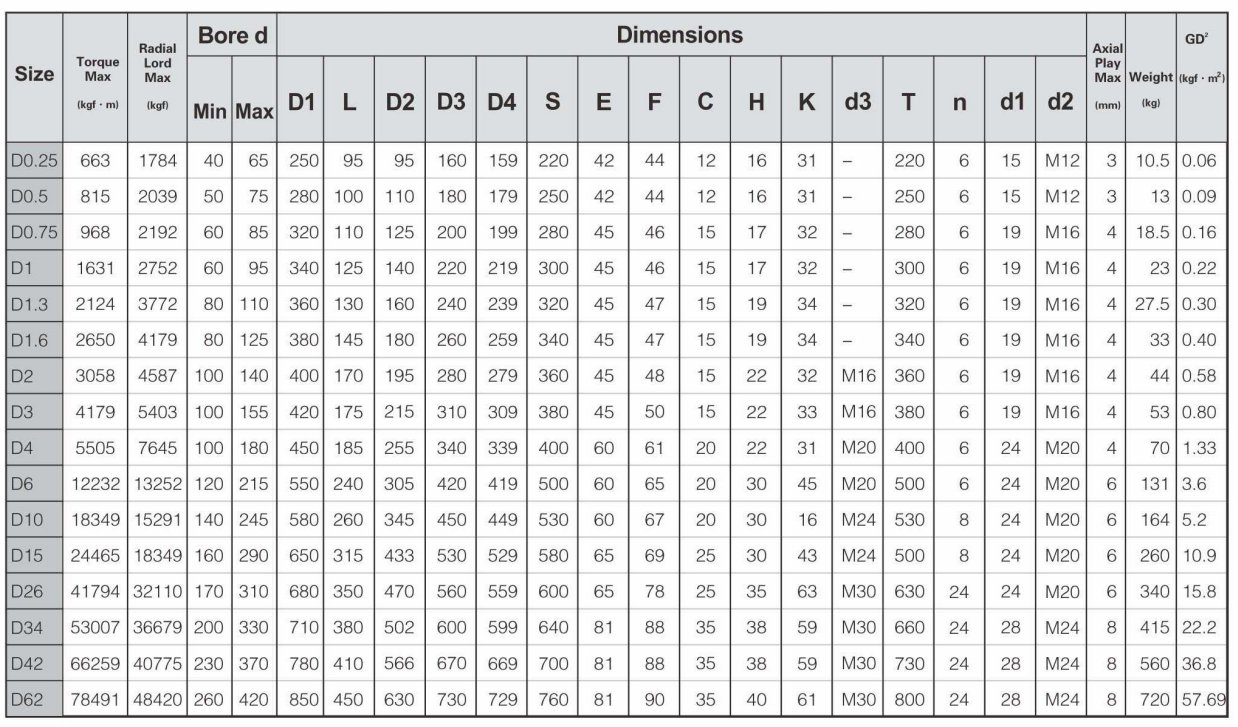

3.Wire Drum Coupling With compact design and capacity of transmiting large radial load, enjoy longer life and minimum loss of power. Angular misalignment can be allowed up to + 1.5

4.According to the size of couplings, max + 3-+ 8mm of end float can be absorbed. Drum couplings are not suitable for transmitting axial forces

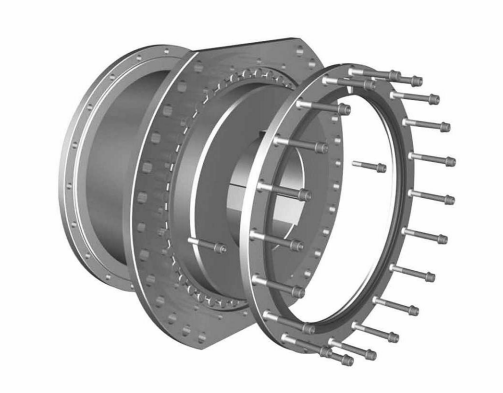

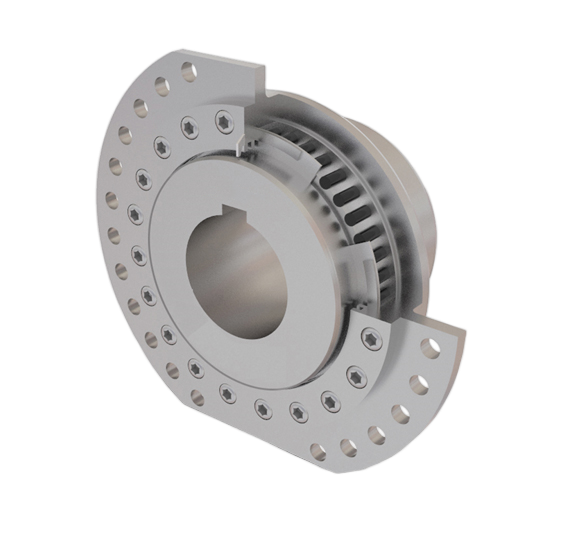

With the design of decreasing slip movement of roller, backlash between crowned rollers and cylindrical bores, the relative movement between rollers and bores, which is caused by wear, are considerably reduced due to the natural movement of drum

In the transmission of power, a stamping hardness of the roller profile is produced, with which higher wear resistance is achieved

- Information

- Download

The Drum coupling is suitable for crane and hoisting construction to couple wire drum and reducer gear box, especially suitable for the heavy and difficult operating condition of iron and steel works.

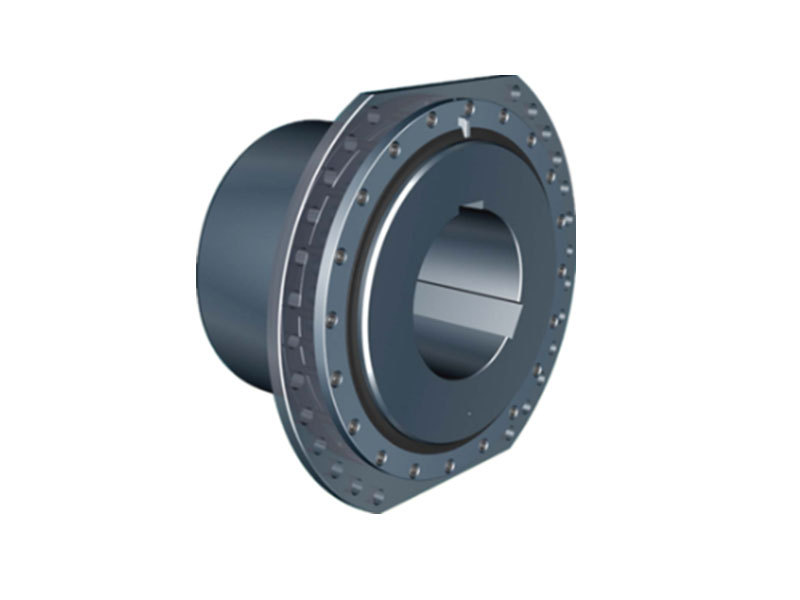

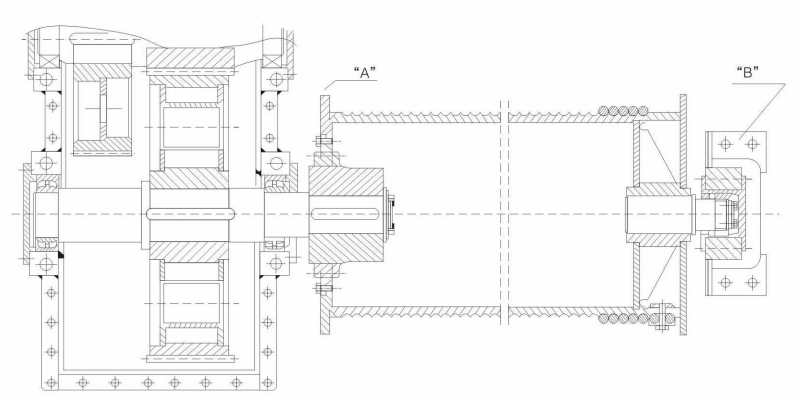

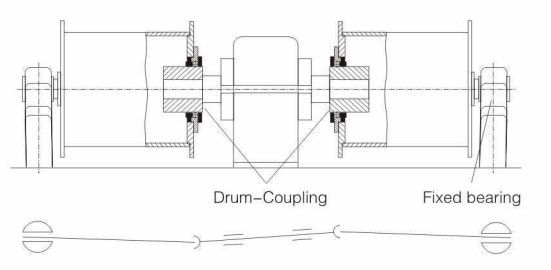

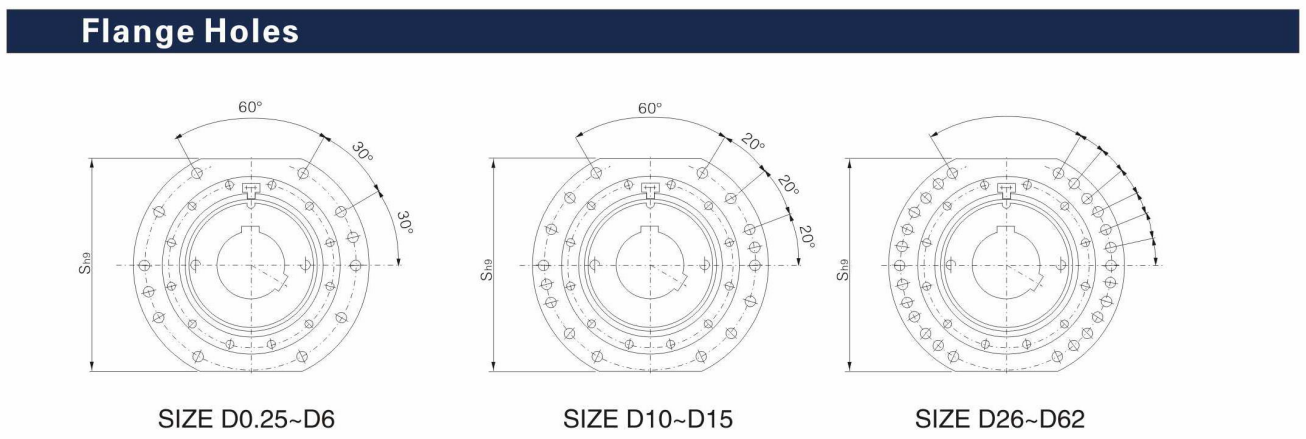

When the gear shaft is connected to hoisting drum with single or twin drive, three or four point mounting is requred for a crane unit. Fig1 and 2 show the arrangement of a drum drive of a crane assembly. These types of connection.

Fig. 1 Diagram of a twin-drum drive without built-in joint

Fig. 2 Diagram of a twin-drum drive with built-in joint

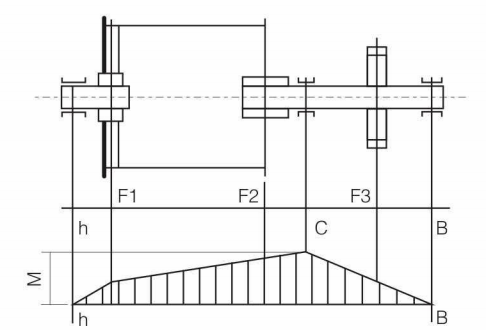

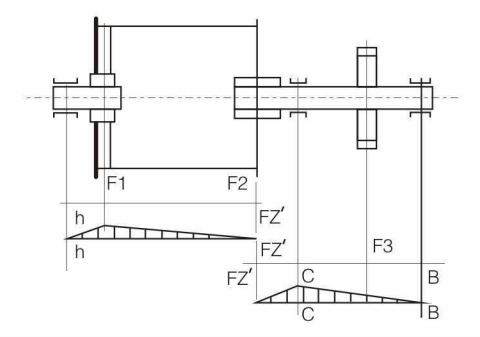

3. In the event of misalignment, which may occur due to inaccurate assembly, considerable additional forces become effective on the shaft, In this case bending stress at the drum shaft occurs during rotation, which can cause bearing and roller damage.

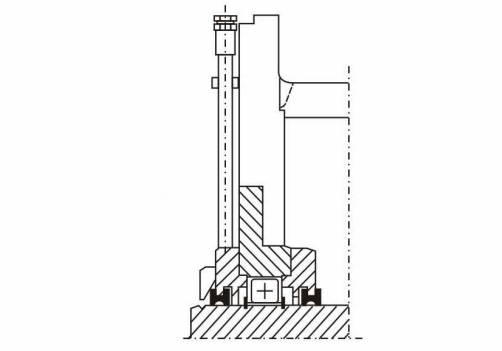

4. In case of a single drum drive with rigid connection of gear shaft and drum, (see Fig. 3) a given load F and bending or alignment error will produce a max Bending moment at the end of the gear shaft and of M.

Fig. 3

Fig. 4

5. bearing is used instead of rigid connection, a joint must be fitted. In this case max bending moment at the end of the gear shaft with the same load F is only 25% of M.

6. The coupling hub of the drum coupling is assembled to the output shaft of reducer gear. The pedestal seat of drum can be designed as a bearing.

Lubrication and Maintenance

After installtion of the coupling into the drum,the lubrication pipe is connected to the lubrication hole.Full up lub-oil must be done before completion of assembly and grease must be forced in until lubricant flows out of the overflow hole.

Operating temperature of grease are-17℃~70℃.The lubrication periods vary according to the types of drive.

Global Group Company

Kudosworld is an industrial technology group with businesses all over the world. We provide a series of solutions, including advanced technology, manufacturing, products and precision services. Provide products and services for key markets such as new energy, oil and gas, mines, ports, steel, etc. We take Kudosworld (China) as the core of operation and management, rely on the technology of Kudosworld in Germany, and cooperate with global production bases for processing and manufacturing. Over the past decades, we have made contributions to the development and implementation of hundreds of projects where product quality, technological progressiveness and reliability are the prerequisites for success. From finding the best customer solution to complex project delivery, customer trust proves our experience, reliability and professionalism.