Horizontal Split Aluminum Grid Coupling

KUDOSWORLD Horizontal Split Aluminum Grid Coupling is the most advanced shaft connection transmission component in the international mechanical field, and it is also very general shaft connection transmission component.

The main structure of the grid coupling is composed of two hubs, two covers, two sealing rings and grids. It relies on the coiled grid embedded in the tooth groove of the two hubs to transfer torque, to achieve the link between the driving shaft and the driven shaft.

In operation, the driven end is driven by the axial force of the teeth of the active end facing the grid to transfer the torque. In this way, the resonance phenomenon avoided to a large extent. Besides, the elastic variable generated by grid when transferring the torque enables the mechanical system to obtain better vibration damping effect.

- KUDOSWORLD

- GERMANY

- 4-6 WORKING WEEKS

- 3,000 SETS/YEAR

- Information

- Video

- Download

Typical application

KUDOSWORLD Horizontal Split Aluminum Grid Coupling is mainly used for driving shaft system with severe impact load, crusher, belt machine, reducer, power plant ball mill, mine winch, gas pump and other crank reciprocating movement, metallurgy, mining and other lifting machinery.

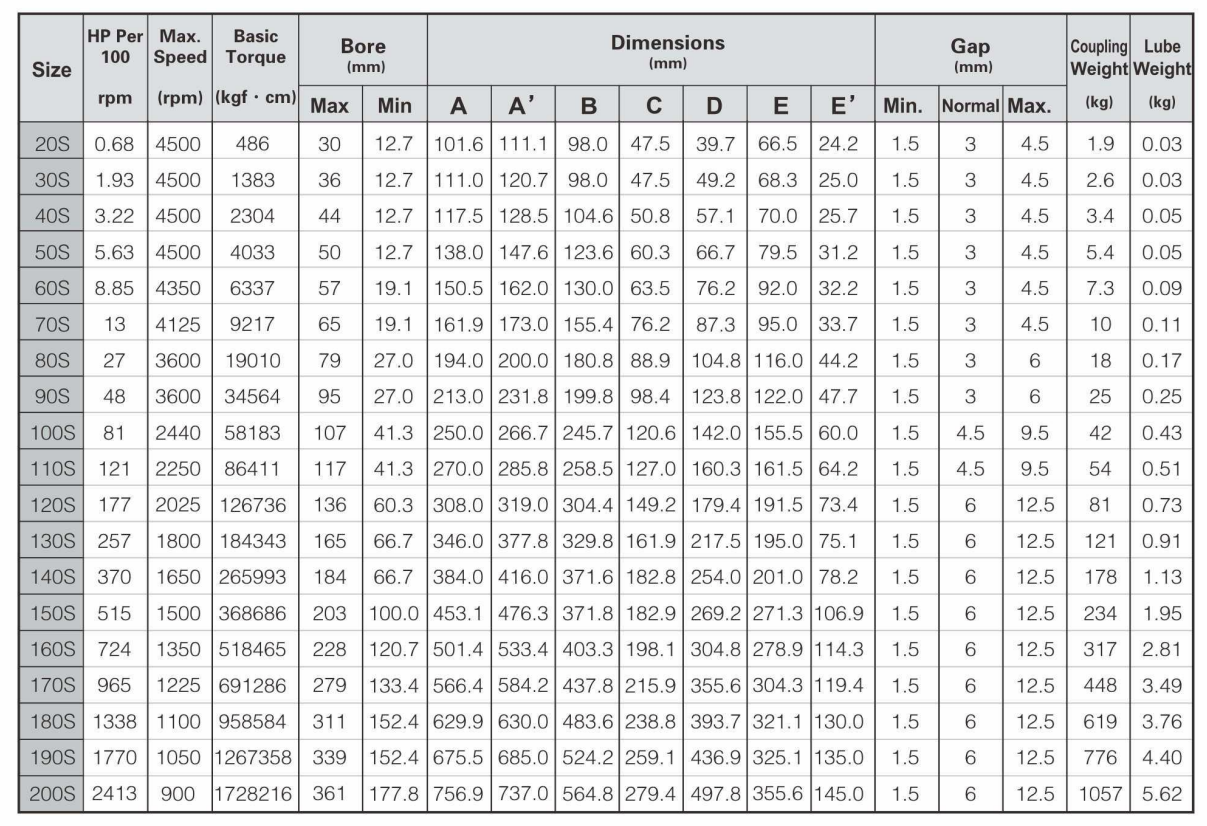

KUDOSWORLD Horizontal Split Aluminum Grid Coupling is available in 23 sizes ranging from SH20 through SH240

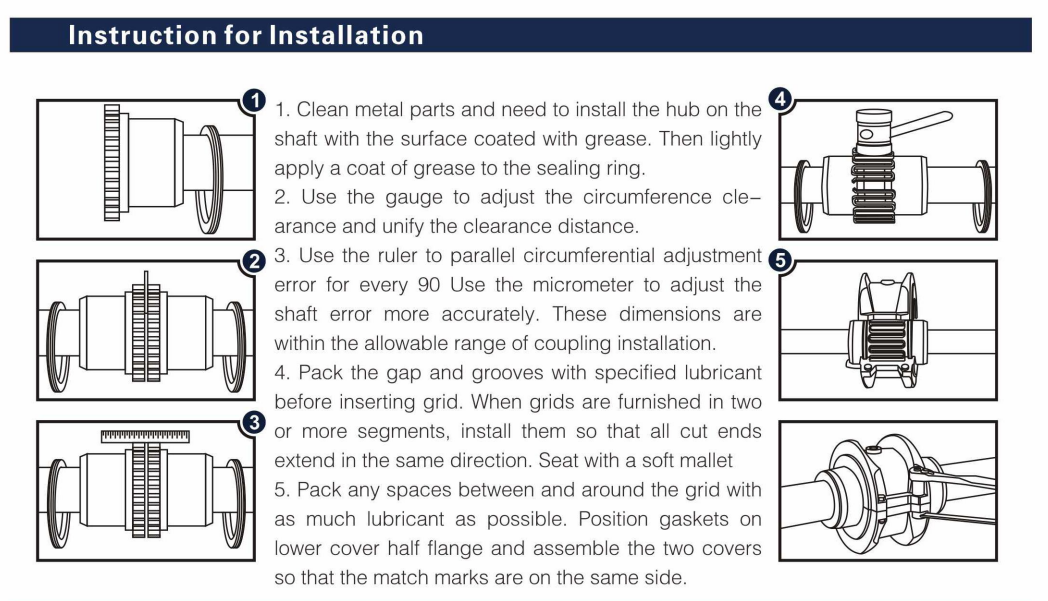

Instruction for Installation

1. Clean metal parts and need to install the hub on the shaft with the surface coated with grease. Then lightly apply a coat of grease to the sealing ring.

2. Use the gauge to adjust the circumference cle-arance and unify the clearance distance.

3. Use the ruler to parallel circumferential adjustment error for every 90 Use the micrometer to adjust the shaft error more accurately. These dimensions are within the allowable range of coupling installation.

4. Pack the gap and grooves with specified lubricant before inserting grid. When grids are furnished in two or more segments, install them so that all cut ends extend in the same direction. Seat with a soft mallet

5. Pack any spaces between and around the grid with as much lubricant as possible. Position gaskets on lower cover half flange and assemble the two covers so that the match marks are on the same side.

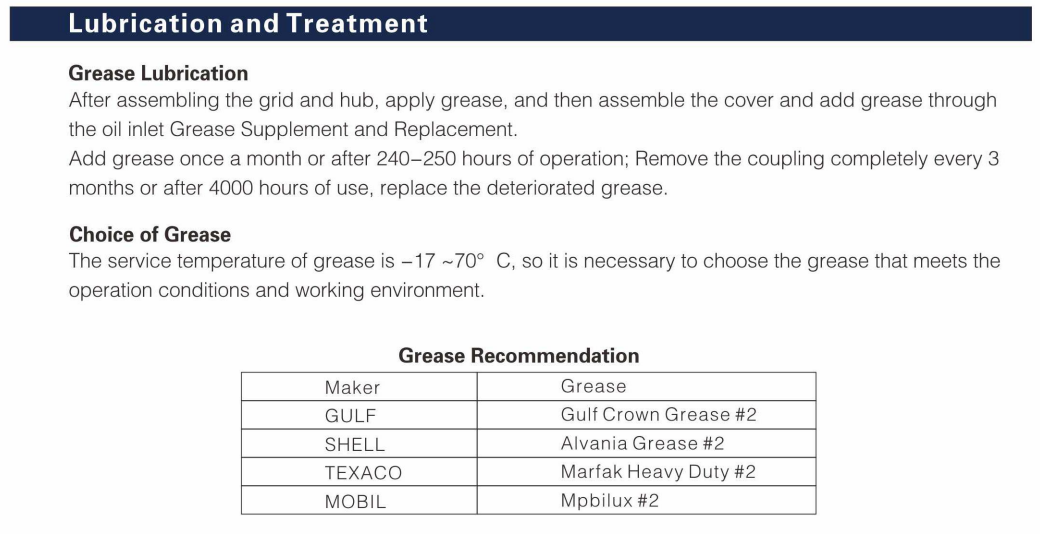

Lubrication and Treatment

Grease Lubrication

After assembling the grid and hub, apply grease, arnd then assemble the cover and add grease through the oil inlet Grease Supplement and Replacement.

Add grease once a month or after 240-250 hours ofoperation; Remove the coupling completely every 3 months or after 4000 hours of use, replace the deteriorated grease.

Choice of Grease

The service temperature of grease is-17~70°C, slo it is necessary to choose the grease that meets the operation conditions and working environment.

Company Style

Kudosworld is an industrial technology group with businesses all over the world. We provide a series of solutions, including advanced technology, manufacturing, products and precision services. Provide products and services for key markets such as new energy, oil and gas, mines, ports, steel, etc. We take Kudosworld (China) as the core of operation and management, rely on the technology of Kudosworld in Germany, and cooperate with global production bases for processing and manufacturing.