Vertical Split Steel Grid Coupling

KUDOSWORLD Vertical Split Steel Grid Coupling is a double-flexing, close coupled, general purpose design ideal for higher running speeds.

Features a vertically split cover which allows for grid replacement without movement to the connected equipment

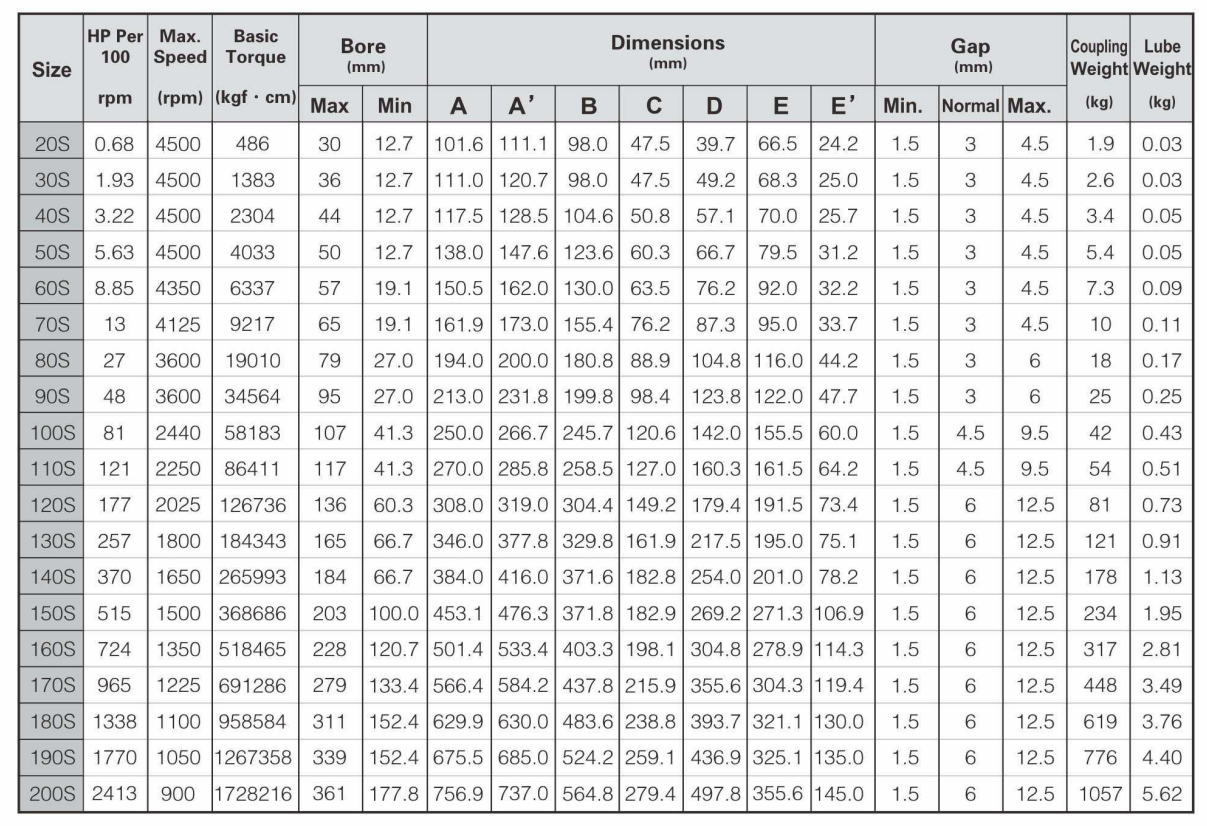

KUDOSWORLD Vertical Split Steel Grid Coupling available in 23 sizes ranging from SV20 through SV240.

- KUDOSWORLD

- GERMANY

- 4-6 WORKING WEEKS

- 3,000 SETS/YEAR

- Information

- Video

- Download

KUDOSWORLD Vertical Split Steel Grid Coupling available in 23 sizes ranging from SV20 through SV240.

-Grid part 860-870℃ quenching and 300-450℃ tempering processed.

-Grid part anti-corrosion: Powder(blue) sprayed on the surface till evenly distributed and completely covered

-Hub material: SM45C

-Cover material: steel

-Concentricity tested after CNC processing.

-Surface treated with anti-corrosion after processing and cleaning.

-Size checking after assembly

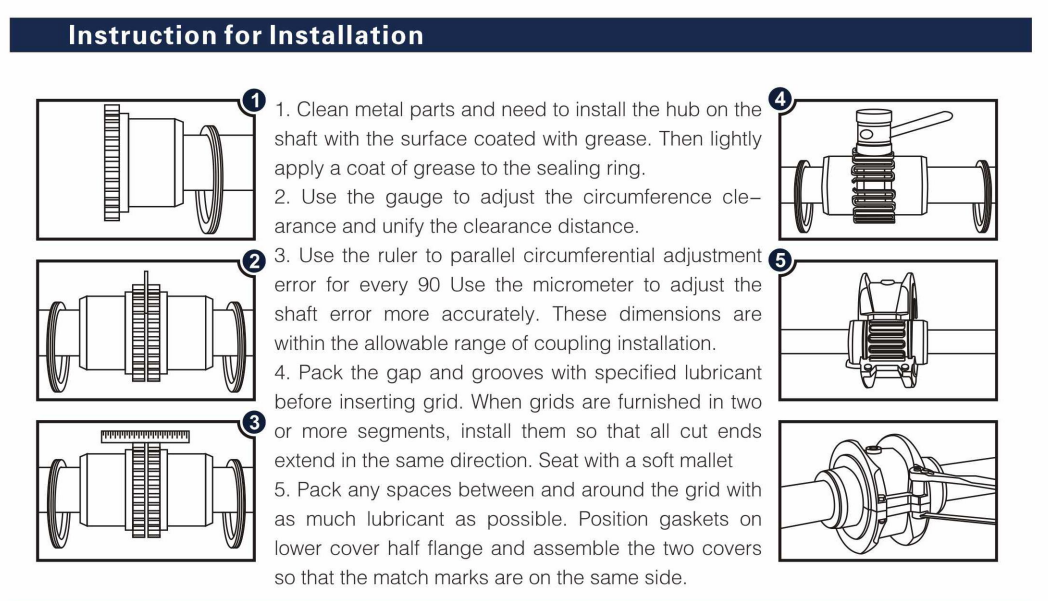

Instruction for Installation

1. Clean metal parts and need to install the hub on the shaft with the surface coated with grease. Then lightly apply a coat of grease to the sealing ring.

2. Use the gauge to adjust the circumference cle-arance and unify the clearance distance.

3. Use the ruler to parallel circumferential adjustment error for every 90 Use the micrometer to adjust the shaft error more accurately. These dimensions are within the allowable range of coupling installation.

4. Pack the gap and grooves with specified lubricant before inserting grid. When grids are furnished in two or more segments, install them so that all cut ends extend in the same direction. Seat with a soft mallet

5. Pack any spaces between and around the grid with as much lubricant as possible. Position gaskets on lower cover half flange and assemble the two covers so that the match marks are on the same side.

Lubrication and Treatment

Grease Lubrication

After assembling the grid and hub, apply grease, arnd then assemble the cover and add grease through the oil inlet Grease Supplement and Replacement.

Add grease once a month or after 240-250 hours ofoperation; Remove the coupling completely every 3 months or after 4000 hours of use, replace the deteriorated grease.

Choice of Grease

The service temperature of grease is-17~70°C, slo it is necessary to choose the grease that meets the operation conditions and working environment.

KUDOSWORLD's elite sales team travelled to Shanghai recently to participate as an exhibitor at the four-day 2020 International Powertrain and Control Technology Asia exhibition (PTC20).

Our logistics:

Payment method: prepayment + delivery payment, special prepayment discount for agents and old customers,

Delivery: According to different product types and order quantities, small models can be delivered in 4-6 weeks, and large models can be shipped in 10-12 weeks

Shipping method: sea, air, international express (small model + small quantity), support EXW, FOB, CIP and other ITEM